|

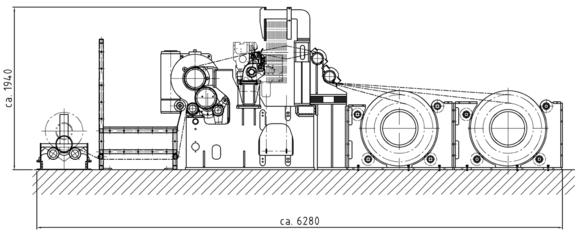

Operation range |

Filtration Fabrics |

|

Weaving width |

up to 14,5 m |

|

Loom speed |

90– 100 ppm for 10 m width |

|

Max. tension |

warp 43.000 N/m beat-up 65.000 N/m |

|

Weft inserting system |

Bandrapier |

|

Number of fillings |

8 |

|

Dobby |

GOF – 94 - mechanic - S & O Hedro-2688 (RS) Stäubli Unival 500 T+ - servo motor driven - Stäubli |

|

Number of harnesses |

up to 24 harnesses in 20 mm pitch (SH) |

|

Loom drives |

Siemens digital AC-Servo |

| Loom control / Monitoring system | Simatic S7 - 1500 + TIA WinCC + Sinamics |

| Energy consumption | 20 - 30 kWh |

|

Operation range |

Filtration Fabrics |

|

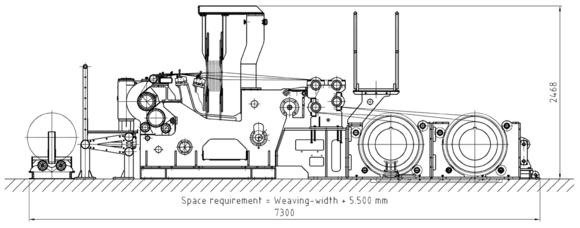

Weaving width |

up to 10 m |

|

Loom speed |

210 - 230 ppm for 6 m width 140 - 160 ppm for 10 m width |

|

Max. beat-up tension |

up to 20.000 N/m |

|

Weft inserting system |

Projectile P 7300 HP D2 Sultex ITEMA |

|

Number of fillings |

6 |

|

Dobby |

UNIVAL 500T - Servo - STÄUBLI |

|

Number of harnesses (weaving) |

18 harnesses in 14 mm pitch (SH) |

|

Loom drives |

Siemens digital AC-Servo |

|

Loom control / Monitoring system |

Simatic S7-400 + WinCC + Sinamics |

|

Power consumption |

20 - 30 kWh |

With sales areas throughout Germany and Europe, Jürgens ranks among the leading specialists for sophisticated castings made of spheroidal graphite iron.

The name Jürgens stands for a wide range of high quality precision products including packaging machines and systems that we manufacture to the highest level technological standards.

Weaving looms are also produced here, including shuttle, rapier, and projectile weaving looms for the manufacture of technical fabrics.